M2 construction panels have the advantages of ease-of-construction and cost savings.

And one huge disadvantage, damage to the environment.

M2 is a popular building material. It is made of Expanded Polystyrene foam board (EPS for short) encased in a wire mesh.

EPS or Styrofoam

Most people know EPS as Styrofoam. Styrofoam is a brand name for EPS.

Styrofoam is created from polystyrene beads. Polystyrene beads are a petroleum-based plastic. The polystyrene beads are processed using chemicals that are steamed, causing them to expand, and creating the substance EPS.

We see EPS used every day as packing materials, coffee cups, to-go containers, and more.

M2 building materials

M2 is an increasingly popular building material. As I mentioned, M2 is EPS (aka styrofoam) panels sandwiched between 2 layers of wire mesh.

M2 building panels are versatile, sturdy and cost-effective. They can be used for a wide range of building elements: loadbearing walls, floors, roofing, stairs, partitions and curtain walls.

The wire mesh allows concrete stucco to be easily sprayed onto the panels.

This system provides a strong wall with a smooth concrete finish.

M2 in Panama

In Panama, M2 is commonly available as styrofoam panels.

The panels come in various thicknesses (2", 3" & 4" thick) and sizes (4' x 8', 10', 12'' & longer panels). (For a stronger house, it is best to use 4" thick panels.)

I have observed the use of M2 over the last 2 or 3 decades, both in the US and in Panama. Recently, I experimented with it in our Living in Panama model home.

Initially, I was attracted to the styrofoam panels because of its speed of assembly.

The panels allow for much faster assembly of concrete walls than is possible using concrete blocks.

Much faster than the typical concrete house construction, which stacks & mortars individual concrete blocks with rebar. Then the cement stucco is applied to the concrete block walls.

(Note: We actually used both M2 and concrete blocks in our Living In Panama House model home, so that we would have a side-by-side comparison of these two construction processes.)

With M2, instead of assembling hundreds of concrete blocks, one at a time, we simply had to:

Using M2 greatly reduced the assembly time compared to any concrete block construction project that I had previously participated in.

For the same sized wall, the cost of the M2 panel materials is higher than the cost of the concrete block materials. But the savings in labor and time more than make up for the higher materials cost of M2.

In short, it is clear that it costs less to build with M2 than with concrete blocks.

However, even before I had tried building with M2, I had had a nagging suspicion that it couldn't be good for the environment, especially at the beach.

Most of us have witnessed washed up styrofoam on the beach somewhere in the world.

Today styrofoam waste is everywhere on our planet. Not a pretty sight. This styrofoam waste poses a tremendous risk to our and our planet's health

Let's talk abit about the elephant in the room.

"What do we do with the off-cuts of M2 that we don’t need for the project?"

"How about the styrofoam "dust" that is created when you cut M2?

At our job site, I saw M2's fragile, crumbly, “styrofoam” nature first hand. This started me thinking hard about whether I should build with it again.

However, what made my decision not to use M2 again final was a family trip to the Chiriqui Mall in David. At the time, they were expanding the Chiriqui Mall to house a department store called, City Mall.

Chemical Snow

As I stood outside the half-completed building, I noticed an accumulation of about an inch of white, styrofoam particles in the gutters. Then I saw that the wind had blown the styrofoam bits into the parking lot and beyond.

Even the light gusts of winds produced by passing cars were enough for the ultra-lightweight styrofoam particles to swoosh and travel through the air.

Clearly, this “chemical snow” was a result of having sawn, ground, or otherwise cut the numerous M2 panels required to build the new City Mall.

It was also quite obvious that there was no plan on the part of the builder, or any other entity, to contain or dispose of this M2 debris.

In short, all these millions and millions of fine lightweight particles were free to be blown, or floated by the next rain, to the nearest drainage culvert, and then into streams and rivers (see photo). No doubt, within 1 or 2 weeks, much of this fine, polystyrene “snow” would be in the ocean. Where it will stay forever. Okay, maybe not forever, just a million years or so.

Obviously, this situation is not limited to Panama. The problem of disposal of EPS waste is worldwide. It is a great equalizer among nations since super lightweight EPS finds its way literally everywhere on our planet.

EPS/Styrofoam's Negative Ripple Effect

Although using M2 to build your home will save you time and money, it does have a negative and compounding ripple effect on the world around you. Check out the bullet points below to get a sense of EPS/styrofoam's impact on us, animals and our planet.

There is a surprising amount of waste using M2.

What do you do with all the window and door cut-outs of your M2 panels?

If dumped in a landfill, over time this fragile styrofoam will be pulverized into small particles. From there, wind and rain carry those styrofoam bits into the ocean.

What to do with any unused or extra M2 panels?

What about all the tiny powdered styrofoam in the grass on the job site?

Of course, you could store the unused M2 for future projects. However, this would begin to mitigate some of the cost savings. You must now also pay for the transport and safe storage of the M2. Or, you would have to give it or sell it to a responsible builder who knows how to handle the product safely.

It seems questionable to give it away to people who are not educated about the environmental dangers of the exposed styrofoam. Without proper care, this styrofoam will definitely make its way into our rivers and ocean.

What about remodeling and demolition of M2 walls? We all like to think that our work is “timeless.” However, the truth is that remodeling of existing homes is constant and shows no signs of letting up.

What happens when you sell your M2 home, and the new homeowners decide to remodel. Let's say you live in your M2 home for 40 years. That is a long time. However, in Styrofoam years, 40 years is only 30 seconds. All the M2 debris from the new owners remodeling your M2 home still has 999,960 years left to contaminate the environment, from top to bottom.

To be perfectly frank, the awareness among many Panamanians of the permanent environmental consequences of their actions is not very high. Just as Puerto Armuelles, feels like a beach town of 50 years ago, so too the environmental awareness movement in Puerto is far behind that of North America.

Concrete Block Construction Advantages

Cement block is the traditional method of building here in Panama. Builders here are reasonably competent at it. Concrete block is strong. With careful attention to detail, you can build a high-quality and reasonably-priced concrete block house.

Plus much of the waste from concrete construction is sand and gravel. Both are natural materials. This means that their disposal will have almost no impact on the immediate environment.

What’s more, it is easy and cost-effective to use any leftover sand and gravel to re-top your driveway or level the ground at the construction site. These materials ‘blend” seamlessly into the landscape, without causing any environmental harm whatsoever.

Negative Impact of Cement

Yes, cement products also have a negative environmental impact. For instance, cement production is responsible for 5% of our greenhouse gas emissions.

However, M2, also uses cement. M2 panels must be covered with a cement stucco to retain its integrity. So not only does M2 use toxic EPS panels, but it covered with cement.

Our Future Use Of M2

After using M2 and doing a lot of research on the product, we have decided not to use M2 again.

I believe that concrete block is currently the most ecological, economical way to build a house in our area.

We are happy to report that our next Living in Panama House will be built entirely of quality concrete blocks. We will use traditional steel reinforcement, grout with a solid concrete slurry and employ a vibrator to remove air bubbles to assure a high-quality result.

However, I always keep tabs on eco-friendly alternatives for building houses in the tropics.

There have been small-scale tests of straw and grass blocks and panels for construction in Europe and North America. Although, these products are probably not suitable for our humid, tropical climate.

However, it is just a matter of time, before more eco-friendly products are developed that are well suited for the tropics. Unfortunately, the oil industry tends to buy up any potential - non-petroleum-based - products that are developed. Therefore, it may take some years until alternative technologies for eco-friendly construction can become widespread.

However, it would not surprise me if bamboo can be used successfully to build excellent, affordable, and eco-friendly houses. It is being used successfully in nearby Costa Rica. (Check out our article on bamboo houses in the tropics.)

Perhaps someone in Puerto Armuelles will discover the next affordable eco-sustainable building material.

If you have any information to share about alternative building methods in the tropics, we would love to hear from you.

If you are an alternative builder who wants to move to the tropics, by all means, come and check out Puerto Armuelles. Perhaps you can help us to develop more eco-friendly housing solutions.

Thanks for reading,

Reyn

Check out our other "building a house in Panama" articles

Ascetic monks from the 15th century and earlier have written about the spiritual benefits of casting off the extraneous luxuries of society and getting back to the bare necessities of life.

The ascetics felt that only without encumbrances and distractions is man truly able to achieve spiritual grounding. Only by practicing simple daily rituals can one enjoy a meaningful life.

Henry David Thoreau got back to basics at Walden Pond in Massachusetts in the 19th century and wrote extensively about the beauty and spirituality that filled his days. Thoreau was quite outspoken in his criticism of common “city dwellers” who were distracted by too much of everything. Of course, Thoreau who lived in the 1800s had no way to imagine the distractions that man would face by 2016. My wife Betsy is quick to point out that Thoreau was a frequent visitor of his mother’s home around mealtime, and that he sent his laundry out to be washed. (I guess it’s tough to be a perfect ascetic).

The early 19th century Irish Poet and academic William Butler Yeats spent many hours “living alone in a Bee loud Glade” in a tiny cottage on the Lake Isle of Innisfree in County Sligo. Many of his poems are situated at this, or other “sacred” natural places. Yet, he also taught writing at University in Sligo, and had a very complex life as a university administrator, husband, father, and community member. For Yeats, a simple thatch hut was a respite from the stresses of day to day living.

The current revival of the small, or “tiny” houses can be attributed in large part to the vast popularity of architect/writer Susan Susanka’s 1998 book “the Not-so-Big-House”. In her book, Susanka asks the basic question of “why does it need to be so big?”

After all, the average size of the North American family has been shrinking since World War II. Yet our houses have been steadily growing. In 1950, the average US home was 1000 square feet. In 1960, it had grown to 1200 square feet. By 1990 it was 2000 square feet. In 2016 the average new home built in the US was just over 2,400 square feet. The only nation in the world with larger homes is Australia where the average sized home built in 2016 was 2,500 square feet.

How did we evolve from a family of four in the 1960’s that fit into a 1200 square foot home, to a family of 2.5 that requires twice as much room? Are we happier now that we have all this room?

Most studies show that the overwhelming reason for the “super-sizing” of North American home has mostly to do with our ability to afford it. Simply put, North Americans have a lot more money than we had back in 1960. In a market driven society, all that money needs to be spent on something. Why not buy a bigger house?

The modern day iteration of the truly “tiny” house evolved from this rethinking of house size that followed on the heels of Susan Susanka’s best selling book. In fact, these days we even try to define what the limits are for each category of small house.

As I mentioned in a previous article, I have lived in a shipping container in Alaska for 2 summers. At 8’x40’ the 320 square foot container was the perfect “tiny man cave” for warming up and sleeping after a long, long day of commercial fishing. However, I would not consider this amount of space (especially the 8’ ceiling height which felt really low) to be a space that I would have appreciated in any other context.

Even my 262 square foot studio apartment in Seattle’s University District where I lived during graduate school, was much a more pleasant space.

This apartment had been carved out of the second floor hallway and a corner room of a hundred year old craftsman house. It had huge windows, and nearly 10’ ceilings. It was much smaller, but it was a perfect city apartment for a busy student on a budget. An added bonus was that my landlord really didn’t care what I did to my unit, as long as I asked first. So, I cut an interior opening between the kitchen and the bedroom to get a view and some daylight into the kitchen/desk alcove. I also installed a new shower and tiled the bathroom.

Rising Interest In Tiny Homes

With the insane rise in home prices in Seattle, and other similar cities, many people, especially the young and retirees on a budget are revisiting the Tiny home concept in order to continue living in the cities which they have come to love and appreciate. Not everyone has an extra $2000 to be able to rent a studio apartment. Many do not want to move out to the suburbs and spend their day commuting to and from the city.

There is a loophole in the maximum housing density law in Seattle which allows Tiny homes to be located on residential property, provided that the home is equipped with functional tires and a trailer hitch. In other words, these “homes” must fit on the roadway and be moved from the property from time to time (I am not sure how often). In other words, the Tiny homes allowed in Seattle are really more like wood framed trailers. As such, the sizes are quite standardized, in order to conform with the building codes as well as the transportation codes. Being so standardized is, from a design standpoint, pretty boring. Most Tiny Homes tend to look alike, sort of “cookie cutter” versions of one another, just with different window treatments, siding materials, and of course, interior finishes. However, the good news about this standardization of size and form is that these tiny houses can be factory built and delivered to your home site pretty much anywhere in the US.

We have had a few inquiries in recent months from folks who already live in Boquete, or in other highland areas of Chiriqui who are curious about what it would take for them to park a trailer, or mobile home on an affordable lot on or near the beach, to use for long weekends, so that they could get their “beach fix” without the having to stay in a hotel.

To my mind, the tiny house concept might be the perfect solution for those who just want a semi-permanent “camp” at the beach that is always waiting for them. I have not priced shipping containers lately, but I think that a shipping container base/secure storage locker could be used as the construction locker/storage unit for beach chairs, bar-b-q, surf boards, etc…so that there would be no risk of break-in in the event that one didn’t have anyone watching the property.

The tiny house, as a short-term accommodation is also a natural rental unit. Many short-term guests to the beach don’t have much luggage, no possessions, and they don’t need much space. Rentals in Puerto are still tough to find. As such, rental rates in Puerto are high. I think it is just a matter of time before some enterprising builder begins to produce tiny homes as rental houses. We have had a couple of calls from guys who have experience building pre-fab homes and tiny homes, already. It is not out of the question that we, ourselves, may build a tiny home or two on one of our properties, so that our clients will have a pleasant place to live while they explore Puerto Armuelles.

Our Ideal Tiny Home Is Bigger

After all our recent researches of tiny homes, Betsy and I are drawing the same conclusion that many others have arrived at before us. That is, Tiny Homes could be just the ticket as a weekend retreat, or a short-term rental. Tiny Homes seem like an amazing business opportunity.

However, when I consider designing a retirement home for my wife Betsy and myself, a small house feels better than a tiny one. I know that I would breathe a little freer in a slightly bigger space than the sub-400 square foot size which defines the truly “tiny” house.

If I had to throw out a number, my own personal ideal size dwelling for a single person would probably fall in the 600-800 square foot range. For a couple, I would think 800-1200 square feet would do well. This allows room for one to be alone for awhile to study, meditate, or practice a musical instrument, without disturbing one’s partner.

Living In Panama House

The Living in Panama House is probably not the final and “perfect” solution to the idea of living a big lifestyle in a small house in the tropics. However, it is the best that I have been able to come up with so far. Believe me, I have given this a lot of thought. I consider the Living in Panama House to represent an honest attempt at a “Not So Big Tropical House”.

As we have been refining the Living in Panama House design, our model has grown a bit, and shrunk a bit. But we keep coming back to about 500 square feet of finished, potentially air conditioned space. This “module which contains the two bedrooms, bath, and a small hallway, is all housed within the “umbrella” of a big sheltering roof. The three-bedroom model is about 650 square feet enclosed. The total square footage of the first model home (two or three bedrooms) is approximately 1,500 square feet.

The Living in Panama house is a bit bigger than my ideal house size for North America, because we think that it is beneficial to have a bit more covered space in the tropics to allow one to enjoy an open, breezy feeling, since it can get hot here. Also, we have more “hang out” time in Puerto Armuelles than we have in Seattle where one just doesn’t have much time to enjoy being at home. So, we end up using our house more here. Betsy and I will undoubtedly adjust the size of the Living in Panama House up or down over time, depending upon feedback we get from clients.

Tiny Home Builders Wanted

If you have any interest in building tiny homes in Puerto Armuelles, we would be happy to help you get started. Drop us a line. There is certainly room for competition in our untapped housing market.

Jan 1, 2017

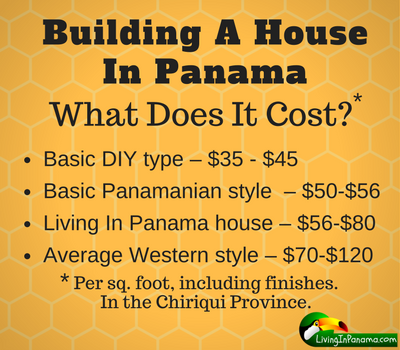

“How much does it cost/square foot to build a house in Puerto Armuelles?”

The answer depends upon what kind, size, and quality of house you are building.

If you build a fancy house, with lots of expensive materials (expensive windows, doors, custom fixtures, etc.) it will cost a lot more than a very basic house. It won’t cost just 10%, or 20% more. Building a fancy house can cost 2 to 10 times more than a very basic house.

In Seattle, circa 2016, building a basic house costs about $200 per square foot. A house with expensive finishes can cost $250 to $500 per square foot (I am not kidding). And it goes up from there. An architect-designed, custom timber-framed, Japanese tea house or fancy outdoor sauna building on the lake could cost over $1000 per square foot

In Puerto Armuelles the answer is the same: it depends upon what kind of house you are building.

Fancy Houses

On the high end, there are wealthy expats who have had homes built on the beach by local contractors. They can easily spend $100/sq ft and more. This does not include the cost of the land.

More Basic Houses

On the other hand, in Puerto Armuelles we have several expats who have been their own contractor and have also done a lot of the work themselves. These folks have completed their projects for under $35/sq ft. Granted some of these homes lack much of a design concept since the owner-builders had not built before. However, the owner/builders appear quite pleased with the results.

I have done a brief survey of costs recently. I took into account my conversations with builders and owners. (As I drive around the Chiriquí province, I often stop by construction sites to chat.) I have also done the usual online research that is available to all of us. Based on these sources, I have concluded the cost figures below.

Cost per Sq. Ft Range

As I read the descriptions of the different grades or qualities of construction available at the various price points, one thing is quite familiar. Just as in the US, the big difference in the cost of construction is in the finishes.

Finishes include:

The finishes vary greatly in price. The cost per square foot for the structure of the house does not vary nearly as much as it does for the finishes.

People understandably want to know how much it will cost to build a house in Panama.

The Living In Panama House has the advantage of being designed by an architect specifically for Panama's tropical climate.

The Living in Panama house is an entire “rethink” of the concept of “home” in the tropics. The Living In Panama house is mostly an open-air living concept. This open-air structure, with just a portion totally enclosed, means that only a small section of the house requires the full complement of finishes. With this type of design, you eliminate the need to pay for extra windows, doors, air conditioners, insulation, or cabinetry. Not that you don’t have those finishes, but fewer of them are needed.

Because of this savings, the Living in Panama House, can be built, including finishes, for between $56 and $80 per square foot. This is a huge saving.

The structure of the house, without finishes, costs an estimate of $30 per square foot for the 2 bedroom model and an estimate of $38 per square foot for the 3 bedroom model.

The cost of building anywhere in Panama varies. The biggest variable is your choice of finishes.

Summary of cost/square foot (including finishes)

I hope this helps to answer this popular question.

We have written about remodeling, various construction materials, and alternative housing types. Click on any of the links below to read an article.

Please share your experiences with the cost of building a house in Panama. Use the comment section below. Thank you.

The house is nick-named “Casa Sombrero” because of its big sheltering roof.

It is on a corner lot in the Corazon de Jesus neighborhood, just north of downtown Puerto Armuelles. The house sits about 100 meters from the beach. While not as windy as a beachfront lot, there is still a good breeze when the onshore winds blow on warm afternoons.

The original footprint of this humble concrete block house was 30'x 22' with two notches removed. Total floor area was about 600 square feet. It had 2 bedrooms, 1 bath, kitchen, and dining/living area.

As you can see by the photos of the original house, it was very basic house indeed. Just a concrete block cottage, with a tin roof, and very few, small window openings that were filled with ventilated cement blocks. Not surprisingly, the original house was hot and stuffy.

Our redesign, in collaboration with a local Panamanian architect, maintains the 2 bedroom, 1 bath of the original small house, but adds an additional 1500 square feet of breezy covered porch space, enclosed by ornamental ironwork.

The open plan is intended to permit the ample porch areas of the house to serve as the primary day use areas. So that most of the events of daytime domestic life can take place within earshot of the sounds of ocean waves and the songbirds of Panama.

The original spaces have solid concrete block walls and large window openings.

This entire original area could be used as an “air conditioned zone.” Or, a smaller area, say just the bedrooms or bedroom, office and bathroom could be air conditioned by a single air conditioner.

The large outdoor porch/living area makes the house much more integrated into the outdoor environment. It is quite comfortable and dramatically reduces the energy requirement of running lots of air conditioning units. If the house had been redesigned as a typical northern home, extensive air conditionally would be required for most expats.

In the first phase of remodeling, we cut numerous new window openings, and enlarged the existing openings.

We also demolished a wall that had divided the kitchen and the dining area into 2 separate spaces.

Since the spaces were so tight, we thought that one big open plan for kitchen/dining /living was better than several smaller spaces. We added ironwork to the window openings, both for security and to give a sense of “completion” and enclosure.

Next, we asked our contractor to build a colonnade around the perimeter of the existing structure. This created wide porches on all sides of the house.

At its widest the porch is nearly 13 feet, and its narrowest about 7 feet. On top of these columns, spaced 9 feet apart, the contractor poured a concrete beam with gently radiused connections at the tops of the columns.

This is a look that we find quite pleasant, and which is quite common in Puerto Armuelles. Bluntly put, it is sort of a “poor man’s Spanish colonial”. It has the old world arches, but lacks the two-foot thick stone walls of Old Spain.

The house was rented to a Panamanian man in this Phase 1 condition for a couple of years. The man lived in the house, rent free, in exchange for maintaining the garden.

The truth is that up until a couple of years ago the real estate market in Puerto Armuelles was not as fast as the rest of Panama. Now our market has definitely begun to pick up. In fact, there were 2 families who were interested in buying Casa Sombrero at the same moment. We ended up selling it to a couple from British Columbia and their four young children.

The new owners appear to be very comfortable building their own homes, which they have done before in British Columbia, including a home on the Queen Charlotte islands.

They hired our general contractor to raise the walls of the existing structure, pour a floor, and to install a new roof. From here, the client is going to take over as his own contractor, and supervise all of the ongoing finishes.

While this Canadian family works on their new home, they are staying in our house in Las Palmas. Since they have young

children, we offered them our house, so that they would have a “gentle landing” into their new life in the tropics. They are apparently quite capable, bilingual, and it appears that they are enjoying a successful remodel.

As you can see from the photos, the roof is on. The owner is working on site every day alongside the Panamanian contractor, and the project is advancing well. The new owner says that he hopes his family can move into their new home by Christmas.

Of course, not all of our clients are interested in, or capable of, being their own building contractor.

For this reason, we offer the option of having one of our Living In Panama House built for them, using the services of one of our licensed Panamanian contractors. We always oversee all our remodeling or Living In Panama House projects.

If have built or remodeled a home in Panama, please share your experiences in the comments below.

Recently, we have talked with a number of people who are interested in building tiny homes in Panama. If you have experience with tiny homes or if you would like to share any techniques for building in the tropics, please add them in comments.

Thank you.

Given that, I was surprised that one of my favorite things to do as we traveled around Panama was to stop by construction sites and talk with other builders. I had fled the hustle and bustle of the building trade in Seattle only to discover, once again, how much I enjoy the fundamental beauty of human “dwellings” and how they are built. Apparently I made a good choice when I chose to become a designer/builder.

It doesn’t take long for one builder, chatting with another builder, in a new area, before the conversation winds its way around to the cost of materials, the cost of labor, the cost of land, to arrive at the potential profitability of being a builder in this new location.

Although I always prided myself on being more of an artisan design/builder than just a financially-motivated contractor, the profit potential in Panama is very seductive.

Early in our Panama travels we met a young builder and his girlfriend at Playa Cambutal. Playa Cambutal is out on the Azuero Peninsula, past Pedasi and Tonosi. They were both surfers and they loved this beautiful surf spot. The young man had borrowed $30,000 (as I recall) from his father who was a realtor somewhere in California. With this money, he and his girlfriend were able to buy a number of oceanfront farms, totaling over 2 miles of beachfront. Amazing!

We all know stories like this, and at first glance, one might say, “Wow! You guys are lucky. I guess we got here too late.” I remember my Dad telling stories about the farm he could have bought in Northern Virginia, a farm that later became Tyson’s Corner Mall.

There have always been great deals. And there will always be great deals. And we are all going to die some day. We still see amazing land deals in Panama.

About 10 years ago we spent some time investigating Pedasi and Tonosi, and other nearby locations. Yes, we discovered some amazing land deals. However, we decided that we were not interested in living so remotely, so far from services. And we had no interest in traveling to check in on any land we would buy in such a remote location.

This young couple (above) explained to us that they had to spend several hours, twice a week, driving to a small town, about 40 miles away, to do their basic shopping. For our own family, spending so many hours on the road, just sitting in the car, and burning gasoline, would not have fit our desired lifestyle. This was the in-the-car lifestyle we were trying to avoid by moving from Seattle. So we left the Azuero Peninsula and chose to live and invest in Puerto Armuelles. If you have read our site much, you will know we are very happy with our decision.

When I am asked if there are any “deals” left in Puerto Armuelles, I have to chuckle.

In truth, the big speculator class of investors arrived in Puerto 12 or 13 years ago. We got here 3 years after the miles of beachfront were sold to speculators from out of town. These same early investors continue to sit on some of the largest tracts of beachfront property in our area. I have no idea how they spend their days. But I am sure that they hardly ever think about our little beach town, unless they are looking at their investment portfolios.

A couple of these “big fish” are now offering schematic drawings of their future plans for these properties, but they haven't started to build yet. Or seemingly will in the near future. Meanwhile, a smaller class of builders, folks like us, is beginning to develop and build.

Yes, there are deals still to be had here. But you will not find the best deals advertised on the internet. You will find them by being here in Puerto.

You need to look around. Decide on your favorite locations and start talking with people. You will start to hear about some stellar deals.

For instance, if you shop, you can still pick up a house, a block from the water, for only $11,000 and a buildable lot for as low as 3 to $5,000.

Puerto Armuelles is a beach town of 25,000 residents, give or take.

It has many good properties and existing buildings, that with a skillful touch can still be resold for a substantial profit.

We want to encourage designers and builders to come check out Puerto Armuelles. To discover if there are any potential projects that suit them in our town. If so, not only will you have a great project, but you can step out of the stressful lifestyle of being a builder, contractor, or designer up north.

If you have experience in alternative energy housing, cooling, and transportation, even better. That is an untapped market here.

There is plenty of room for competitors in our market. Puerto Armuelles does have a few good builders, but we definitely need more motivated and skilled investor builders to provide housing for the growing influx of expat retirees. More good builders will just bring a greater diversity of expats and Panamanians to enjoy the lifestyle that Puerto has to offer.

Small-scale projects are definitely in demand. We recently sold a couple of our own projects. We did not make ten, or even five times our initial investment, but we have done well enough to carry us forward. Plus we have had a good family adventure and enjoyed our time doing it. And we have also slowly evolved our guiding design principles for building in our area. We are eager to continue to buy, to build and to sell.

We are excited by the uptick in the housing sales market. This enables us and others to design and build in a manner that inspires us, and that we think will be useful to new expat residents of Puerto Armuelles.

Our friend Victor describes life in Puerto Armuelles as being similar to that of Hawaii, or Southern California of 50 years ago.

You may find Puerto Armuelles is a more relaxed, and probably a more profitable building environment. And you won't have the stiff competition from other builders.

The broadest market niche by far available to expats in the construction field is that of “investor/builder”. You don't need a work permit to work on your own property, even if your intent is to sell it.

However, for the last few years, Panama has made getting a work permit much easier. This is especially true if you obtain the easy-to-get, Friendly Nations visa. That permanent resident visa was designed as a stepping stone to a work permit.

If you are a builder looking for a change in lifestyle, we invite you to check out our town.

For the builder who loves a beach town lifestyle, I would say that Puerto Armuelles is similar to Puerto Vallarta 50 years ago. It is a relaxed, maritime environment. And it probably won’t be like this forever.

Related Reading

You may be interested in reading my articles about building. I have given my 2 cents on

We have also written about these related items:

“When I grow up,” Paul proclaimed, “I am going to build myself a house out of trash”.

(FYI - He never did build a house of trash. He teaches painting at Penn State)

I certainly wasn’t interested in living in a house made out of trash. It sounded kind of, well, trashy.

That was in 1979.

Fast forward 30 years, and nobody calls it “trash” any more.

Today we use the terms “recycled material” or “Post Consumer” material. We’re all building out of recycled materials, whether we realize it or not.

The fact is that many parts of our homes are made out of “trash” today. Thank goodness for recycling.

With 7 billion people living on the earth, and with the continued promotion of the “American Dream” (ie, a high consumption, high environmental cost, standard of living) there is going to be an ever greater need to get creative about using recyclables in home construction.

In Seattle, where our family is from, many creative remodelers and builders visit the Boeing Aviation Surplus Store to find such crazy building products as aluminum honeycomb fusilage, or solid aluminum bar stock “I-Beams”, and you name it. It’s pretty high tech stuff, but it appeals to a certain type of designer builder.

For instance, on an loft apartment/art studio project in which I participated, our crew used aluminum honeycomb panel fuselage material as the floor in a sleeping loft. Aside from being super cool to look at, since the hexagonal cells of the honeycomb were visible on the exterior sheet surface, the material was so rigid that it required no structural supports, other than the perimeter walls. Obviously this material calls for a different approach to building (ie, practically no framing support). This results in a very clean, ultra modern look. It wasn’t a look that I particularly liked for a human dwelling. It wasn’t traditional, cozy, or “homey”. Rather, it was “defiant”, “impervious”, “edgy”. It certainly challenged the viewer’s normal sense of what constitutes a home.

Of course, you can also find much more traditional recycled building materials in Seattle. There are many, many recycled building supply centers in Seattle, as there are in most metropolitan areas of North America. You can find old fir warehouse beams, recycled bowling ally floors, stained glass from old churches, antique bar mirrors and surrounds from 120 year old hotels.

When one comes to Panama, one doesn’t think about recycling. Most buildings are pretty new and made of cement.

However, Puerto Armuelles is unique here. What we have is a company town, former home of Chiquita Banana Company. “The Company” as it was known, imported most of the materials used to build the town of Puerto Armuelles, literally from the ground up.

If you have ever get the chance to explore inside an old Chiquita Banana house, up on stilts, you will surely discover lumber stamps from Portland, Oregon where this gorgeous, old-growth red cedar was milled well over half a century ago.

If you know anything about lumber, then you also know that the quality of the 2”x4”, 2”x6, 2”x8” framing material, as well as the 8”x8” and 8”x 10” support posts and beams is of such standard that has not been available as building material in North America for decades.

If one purchased it in the states today, the wood in the old Chiquita Banana Houses would be considered “furniture grade” and probably cost in the $15-$25 range per board foot—prohibitive for home building. I wouldn’t be surprised if our own house in Las Palmas contained over $50k worth of clear, old growth cedar.

If you look at the tightness of the growth rings, you will see that none of these trees could have been younger than 1000 years old. I love this beautiful old wood. Still, I’d much rather see the wood in the forest than in my house.

In addition to clear, old growth cedar, some of the more recent vintage Chiquita Banana Houses are built using the identical plan as the original Chiquita houses.

However, the newer models, dating from 25, 35, even forty years ago, are built from other exquisite woods. That is, these houses are built of dimensional lumber logged directly from the jungles (now, former jungles) of our own Punta Burica.

Just as the original Chiquita houses were built of ancient Cedar trees, so the newer generations of Chiquita houses are built of local, but equally ancient forest trees. Species such as Teak, Sangrio, Espave, Kirra, etc. A couple of these woods, particularly teak have very good resistance to termites. Sangrio and Kirra are gorgeous furniture quality hardwoods that are really too hard to be good framing material. They require pre-drilling, prior to sinking a nail.

As for the logic of cutting down a 10 foot diameter ancient rain forest tree in our local jungle just to make an 8”x8” structural post or beam in a Banana Company house, some of us have different views. I suppose back in the days of Chiquita Banana in Puerto Armuelles, nobody ever thought that the world would ever run out of wood. If you are from Canada, it might seem that there is still an endless supply of old growth trees.

I am not suggesting that one purchase Chiquita Banana houses and begin disassembling them and loading them into containers for export. But, rather, I am saying that there is a huge quantity of amazing building material available for those who are on a tight budget, but who have creative energy to burn.

Many of the original Chiquita Banana houses have fallen into disrepair. Since the local builders have a strong preference for building with concrete, many of these Chiquita houses just get scrapped, or used as concrete form boards.

A thorough search in the various neighborhoods of Puerto Armuelles would surely turn up some excellent salvage. I am guessing that one could purchase adequate salvage material from old Chiquita Banana houses to build an amazing beach house, for a couple to 5 thousand dollars.

This includes studs, joists, cedar siding, and super heavy duty galvanized roofing. There are still even a few old Chiquita hand washing sinks and toilets floating around in town.

I do not want to contradict what I said earlier about wood not being a desirable building material in our coastal/tropical climate. I stand by that opinion, if you are building a conventional house, using conventional methods and utilizing the labor force available in Puerto Armuelles at the present time.

Find out more, by reading why you shouldn't build with wood in Panama and why remodeling a wood home is not the best idea.

However, if you are artistic, high energy, and want to build something super inexpensive, something that is truly unique, and truly yours, building with Chiquita salvage could be ideal.

I think you might be able to come to Puerto Armuelles, buy a bargain priced lot for under $5k, and put up a completed structure, made primarily of recycled Chiquita Banana surplus.

The final product would be limited only by your own skill and imagination. This entire home could be built for well under $5k (total price for house and land under $10k).

Obviously, this sort of a challenge, and this kind of lifestyle, is not for everyone. However, if this sort of thing sounds like a fun adventure to you, you have come to the right place. Puerto Armuelles is a great place to experience this sort of an “alternative” eco- building lifestyle.

I have only mentioned Chiquita wood salvage so far, but Chiquita Banana imported other great materials as well. For instance, you will notice shortly after arriving in Puerto Armuelles, that many of the local fence posts are made from railroad rail, salvaged (stolen?) from the narrow gauge Chiquita Banana railroad tracks.

These tracks ran from the banana fields all the way to the shipping pier in downtown Puerto Armuelles. The train also ran to David. Some folks have reused this rail to build house posts, beams, storage buildings, hoists, racks, etc…

Imagine a practically unlimited supply of railroad rail. If this starts your mind thinking of possible projects, then you are the person I was hoping to communicate with in this article.

In addition to railroad rail, Chiquita imported miles of steel plumbing pipe, as well as some super thick walled steel tube section, both round and square.

Some of this material is still being sold just for its scrap iron weight. However, the salvage market is certainly getting more competitive, as materials prices go up. However, it depends on how good a scavenger you are.

If I could show some of this Chiquita Banana salvage to my friends from architecture school, they would probably have heart attacks. All this salvage, and very few people who have the design skill to take advantage of it.

If you have any questions about recycled Chiquita Banana building products, or about alternative building methods, in general, please contact us. We are always happy to share with you what we know, and we are eager to learn anything that you might be willing to share

At the end of this article, I also briefly discuss remodeling a cement house.

I have spent my entire career building with wood: in Seattle, Alaska, even in Japan. So it seems strange for me to take such a strong stance against building with wood. Especially in Puerto Armuelles, which initially was built entirely with wood. The United Fruit Company, later Chiquita Banana, built Puerto Armuelles from the ground up using red cedar 2x4’s they shipped down from Portland Oregon.

I suppose if I were 36, or 46, rather than 56, I might feel differently. Or if I hadn’t already spent half of my life remodeling houses. Or if the weather were cool, as it is in Seattle, or Alaska.

I have met guys from various parts of the south, including Houston Texas who have told me that “Where I’m from it is 20 degrees hotter today”. These guys work in blue jeans in Panama. I have spent the better part of my adult life in the Pacific Northwest. On the hottest days in Panama, I sweat just standing still.

I guess what I am trying to convey is that it depends a great deal on the personality, and talents of the potential remodeler. If you are one of those men, or women, who has a tough time sitting still, or if you have looked forward to retirement so that you would have time for projects like remodeling an old Chiquita Banana house in Panama, then remodeling and old wooden house here might be just your cup of tea.

If you can pick up an historic, wooden Chiquita Banana house cheap and in good condition, it might be worth it. (Don’t forget to read the section on “termites” in my article on building with wood. Termites abound in coastal Panama, and they love to eat wood.)

Ten years ago wooden Chiquita homes in Las Palmas were going for $10,$20, $30,000. However, the current asking prices for the nicest homes in Las Palmas is in the $120k-$350k range. You can still pick up a deal, but the house is unlikely to be in good shape.

I would advise, as with any purchase in Puerto Armuelles, that you take your time, ask around. Eventually, you will find what you are looking for at a price that fits your budget.

In some of the less elite neighborhoods (that paradoxically are closer to the beach) deals are easier to come by. I think that, with patience, you still might be able to buy a wooden house in Carmen for under $14K, possibly even $11k. Carmen is a densely populated, working class neighborhood (noisy on the weekends). But Carmen is very well located on the ocean breakwater, at the south end of the downtown. The quality of the houses is already slowly improving in El Carmen, due to an inflow of new money into town. Many locals, even a couple of expats, are repairing and remodeling in Carmen. Prices can go nowhere but up.

Pressure treated 2x studs are available in David, imported from Canada and Chile, I believe. But they are expensive. At my last investigation, 2x6 pressure treated hem-fir cost over $2.00 per lineal foot. Prices may have come down, due to increasing demand; In the near future this may not be an unusual product anymore.

(Important note: I am not certain that I would want to live in a house made of such toxic wood, particularly if the framing lumber was left exposed. If that happens, the homeowner would end up in direct daily contact with the pesticide- impregnated wood.)

2. Labor cost. Another serious consideration when deciding whether or not to remodel a wooden house is labor cost.

On a per day basis, construction labor here in Puerto Armuelles is a steal. Workers get $20, $25, and $30 per day here. However, they don't have much experience working with wood. This means the efficiency level of these laborers is nowhere near a professional building crew in the States or in Canada.

A small 2 or 3 bedroom house that 2 skillful carpenters might frame in the States or Canada in a few weeks, could well take a crew of 6 men here several months to complete. And complete with a far lower quality of fit and finish. It is just not a woodworking culture.

There are those who would respond immediately “No Way. Don’t remodel a concrete block house. Far better just tear it down and start from scratch.”

I know from conversations with Milton Hutto, owner of Heavenly’s Hotel in San Vicente that he felt that he should have torn down the existing concrete house that became part of the West Wing of his hotel.

Most of his project was built using M-2, steel rebar, and concrete stucco. Obviously, Milton knows what he is talking about. He was there on-site during most of the construction, and he had prior building experience in Puerto Armuelles.

Watch a video of Milton talking about building a house in Panama, as an expat. Just click the link.

However, one should consider the scale of the project, before dismissing remodeling a concrete block house out of hand. In Milton’s case, he was building an 11 room hotel, not a small, single family, or single person dwelling. He employed a crew of at least 10 men. With this work force, costs were high, and quick progress was an absolute necessity.

Find out about building your house of concrete in Panama.

Betsy: Hi, Milton.

Milton: Good morning.

Betsy: I know that you have built a house or two and also this hotel, which we're seeing in the background, Heavenly's Hotel

What do you have to say about building a house here, for expats?

Milton: Building is relatively pretty easy.

The process of getting it done is not that bad. If you find you a good contractor, it’s a really smooth process.

Materials are very available to the standard. A lot of it's not gonna be to American standard, but the standard's good for where you're at.

Betsy: Thank you very much, Milton.

Milton: You're welcome. Thank you.

Concrete, along with M2 panels and Plycem, is the main building material Milton uses to build in Panama.

Concrete homes are typically the easiest and cheapest houses to build here. My husband Reyn, recently wrote about why cement is a good way to build in Panama.

But there are other materials you can use to build your house. Click on the links below for more about each.

The issues with building a bamboo house in Panama

Remodeling or building wood houses in Panama

Using shipping containers for your home in Panama

Reyn also wrote a post with 6 questions to ask about the construction materials to use for your house in Panama.

I am particularly interested in ways to keep a shipping container's living space cool, comfortable, and affordable in the tropics.

I recently heard that you can buy a used shipping container in Panama, delivered to your site in Puerto Armuelles, for under $3000.

This price appears to fluctuate widely based on the global economy.

When business is booming, containers are scarce, and thus expensive. When markets are down, there are more abandoned containers since there are fewer goods to be shipped.

As far as shipping containers are concerned, I do have a bit of experience. I have both fixed up a container as a basic living space and visited some high end container living spaces.

A couple of my Seattle designer/builder friends have created “gourmet” shipping container buildings. I have visited those units. So I have experienced how a shipping container can be transformed into an artistic home.

One of my friends, Hartman Kable, created a modernistic take on the surfer “shack” using a shipping container. It has been featured in various magazines, including Make Magazine's video below. The publicity earned Hartman a trip to the east coast to do another similar project for a high end client.

I like that Hartman kept the look of the container. He didn't radically transform the container so that it was hard to see that the base building material was one or more shipping containers.

Hartman gives a tour of his cool container surf shack in Make Magazine's video below. I'd recommend skipping their very long intro and going directly to Hartman's tour at minute 1:25.

[leadplayer_vid id="579B56D30E20D"]

(Note, Hartman built this on the Olympic Peninsula in Washington State, which has a very different climate than Panama does. You would need to add air conditioning to use something like this in Panama.)

When I was commercial fishing in Alaska, I spent 2 summers living in a shipping container. The container was delivered and leveled right next to the cabin of my employer. This was on the bluff above the mouth of the Egegik River on Bristol Bay in SW Alaska.

One of my pre-season projects was to outfit this 40’ container as a combination net shed, work shop, and crew quarters. The remodel had to be simple because of our very limited supply of building materials. We had to use what we had since we were out on the tundra above Bristol Bay, about 200 miles away from Anchorage, .

The container was an insulated refrigerated model with teak paneling and floor. (Note: most containers are not insulated). It cost $1000 at the time, delivered to our site. So it was affordable. Certainly cheaper than building a similar structure out of more typical materials.

In our wide open, cool, windy tundra base camp, the container was perfect. I put a heater in it. I easily stayed warm. I slept very well since I was always exhausted after the days work. (A long day being 20 or 30 hours of fishing without sleep.)

The container was a secure cocoon in an environment where the wind often blew 50 miles an hour. Our summertime high air temperature was usually around 50 degrees Farenheiht, and the water temperature was in the mid to high 40’s. In a word, my container building was “snug”.

Conversely, in our tropical environment here in Puerto Armuelles, “snug” is not a good thing.

If you look at an indigenous tropical hut, what you will observe is a roof and support for that roof. Not much more. There might be some lightly woven mat walls or bamboo to provide some privacy from neighbors, and a little extra shade.

Generally a good building type for the tropics is a lot like an umbrella. Shade, Shade, Shade, plus, protection from the rain.

In a perfect tropical world, walls are not necessary at all. They are a hinderance to air flow and evaporation. We northerners mostly like them, because they afford privacy, and security.

In fact, while Panamanians are often cold at night and in the early morning, most northern immigrants, except in the highlands, do not require walls for warmth. Our need for walls is generally for privacy, security, and in large part, because we grew up in houses with walls. We just think that houses “should” have walls.

The challenge is how to make a cool and comfortable container house in Panama.

The easiest way to do this is to keep the sun off your container. Solar gain is the biggest factor in hitting up your container home.

A site called containerhomeplans.org specifically discusses what to do to keep your container cool in Panama and elsewhere.

Read more details at containerhomeplans.org here and on this page.

As I have mentioned, ventilation and air flow is a huge factor in keeping living spaces cool. Tropical houses are typically designed to maximize air flow for this reason.

To achieve adequate cooling air flow in a shipping container, requires that you modify the container. One example of what that could look like is seen in the South African classroom photo.

However, if you like the idea of closing up the container as a secure pod, you cannot do that. (Watch the video above to see how Hartman is still able to secure his container using the original container doors.) You will need to use air conditioning. You may even want to use a portable air conditioner so you can safely store the A/C unit inside the container.

Successful Container Housing In Panama

People have been successful in creating container housing in Panama. A couple who created a home using multiple shipping containers near El Valle, Panama. They detailed how they built it in their blog.

It took them 5 years to create their container home (see photo). In the end, the amount of work they did to create their container house means that it is not the cheap and easy option that attracts so many people. They are currently selling their home for more than half a million dollars.

My Opinion

In short, my opinion of shipping container construction in low-land tropics is low. I don't enjoy living in air conditioned spaces with low ceilings. It seems clear that without a tremendous amount of work, that is the type of container house you must live in here.

I don't think using a shipping container is a good option for a pleasant home here in Panama. You can build a much more pleasant Panama house using cement - and it is affordable. You can either use formed and poured, or concrete block (the most common method) for your new home.

Containers do make great tool or other storage, if you can find one at a good price. Keep in mind that, if left in the sun, the interior temperature of a shipping container is likely to reach 160 degrees Fahrenheit. Of course, you can build a roof over your shipping container to provide some protection from the sun.

If anyone has more information, contacts, or websites to share, I am certainly eager to learn more about shipping container construction. I think our readers would also be interested.